-

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

-

Wechat: a18350222213

Wechat: a18350222213

-

Time:1/7/2026

-

Time:12/30/2025

-

Time:12/18/2025

-

Time:12/10/2025

- CONTACT US

- Wechat: a18350222213

- aceally4@aceallygroup.com

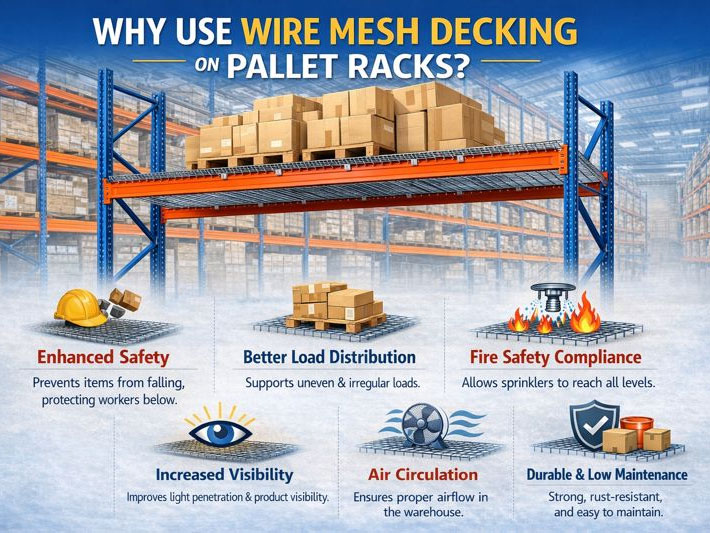

Wire Container Standard

Time:5/15/2019

Time:5/15/2019 258

258

1 The Definition of Wire Container

Wire container is mainly composed of low-carbon wire rod and plate material, it’s light and handy, in addition to the base part is made by the plate and wire, the rest parts are only made by the wires welded via resistance welding machine. It is connected by using spring-type spiral wire between the mesh panel and mesh panel, very flexible. Stored goods when stacked with each other, the upper wire container weight on the side meshes of the bottom wire container, the front door can still be opened to access the goods. The maximum load of wire container is 2 ton /set and stacked 4-high, which means the lowest wire container can hold up to 8 ton. The important technology to guarantee the security of the wire container is the wire material used, the welding quality of wire meshes, wire mesh and base, base and feet. This article specifically introduces about the technology and specification of Eastfound’s wire container.

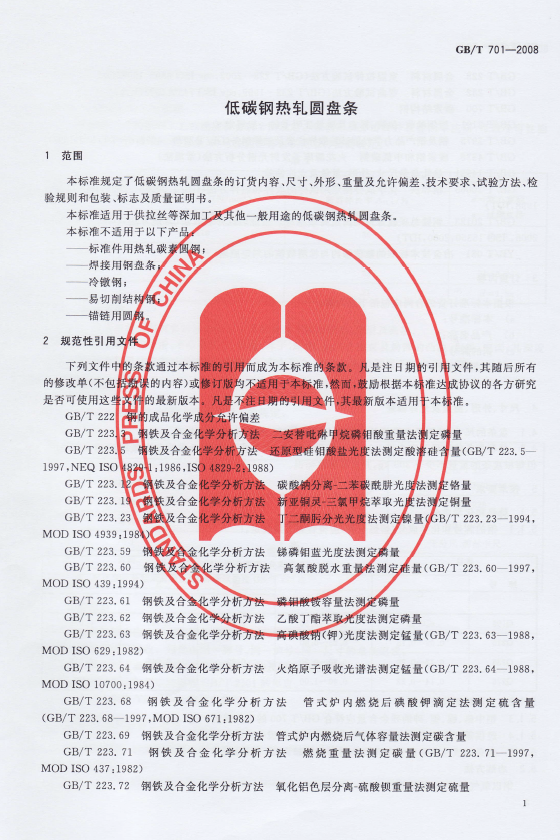

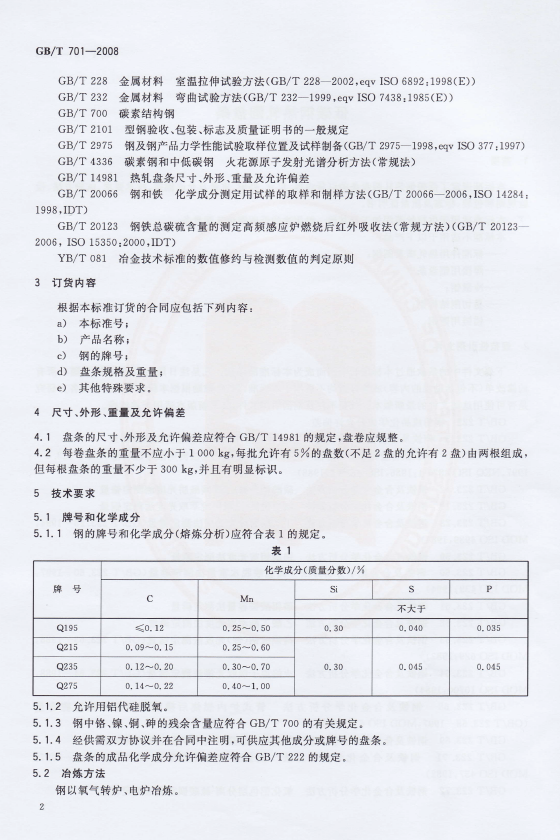

2 The Wire Material We Use2.1 Regarding the Chinese National Standard (GB) and the Use of Steel Q235

The Manufacturer of wire container in China, are generally use Chinese national standard (GB) Q195 or Q235 wire.

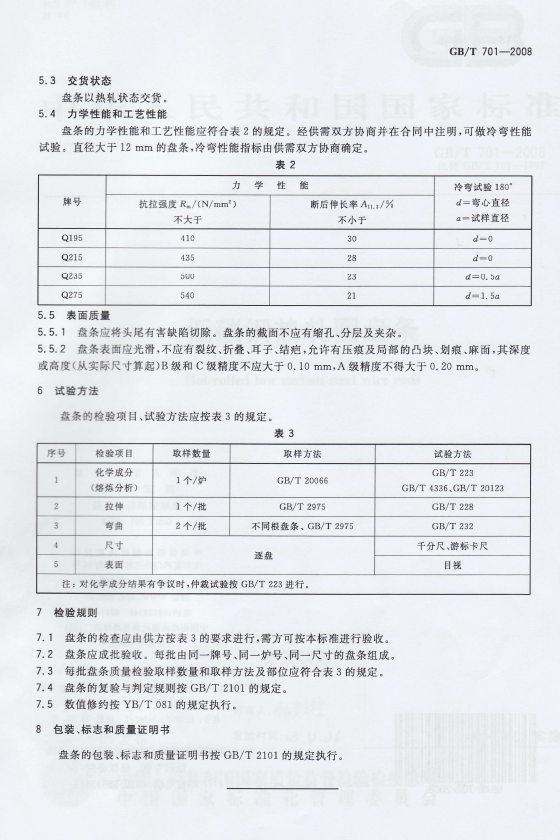

The GB standard Q195, Q235 is named by metal material yield point value. Q195 means its yield point is not less than 195 N/mm2, the tensile strength is less than 410 N/mm2 . Q235 means its yield point is not less than 235 N/mm2, the tensile strength is less than 500 N/mm2. Therefore, the yield strength of Q235 is higher 20percent than Q195, so does the tensile strength , which Q235 is higher 20percent than Q195 too. (Please refer to mechanical properties of Chinese national standard T701-2008). In simple terms, the Q235 material is harder 20percent than Q195.

The Q195 is soft material, it is easy to process and welding, on the other hand, the Q235 material is harder than Q195, the strength is good, but the resistance welding characteristics is not good, not easy to process and welding.

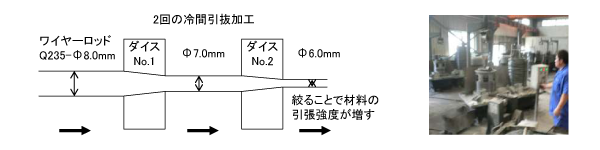

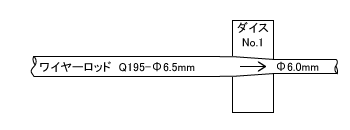

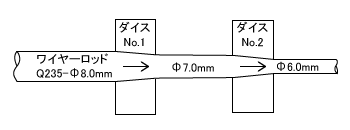

However, in order to guarantee high strength and security of the wire container, all the wire material of wire container we use is (GB) Q235. At the same time, in order to improve the strength of the wire, our wire material is drawn two times, firstly from Φ8.0 mm to Φ7.0 mm , secondly drawn fromΦ7.0 mm toΦ6.0 mm. To ensure the welding performance of drawn wire, the wire panels of wire containers are welded by high-power Swiss Schlatter automatic resistance welding machine.

2.2 The Comparison of Wire Material of Chinese National Standard (GB) and Japanese Industrial Standard (JIS)

There is not exactly the same wire material in JIS as that of Q195 and Q235 in China. The most close to this material is as follow.《China's national specifications T701-2008 》

|

|

|

|

The Chemical Composition

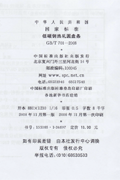

The reason of broken when wire is welding is due the high component content of P and S.

The component content is not higher than 0.03, 0.035, 0.04percent in the GB or JIS standard, but that of P and S in the wire material our company purchase is 0.014 ~ 0.021percent, shown in the picture on the right, only half as standard, so it doesn't need to worry about the broken of wire welding.

The instance of welding broken of wire container is due to the high content of P.

The chemical composition of P of the wire material is 0.038percent, higher than the standard. The resistance welding of wire was broken in the impact and the cold bending process. This is the wire material that is not guarantee the welding quality.

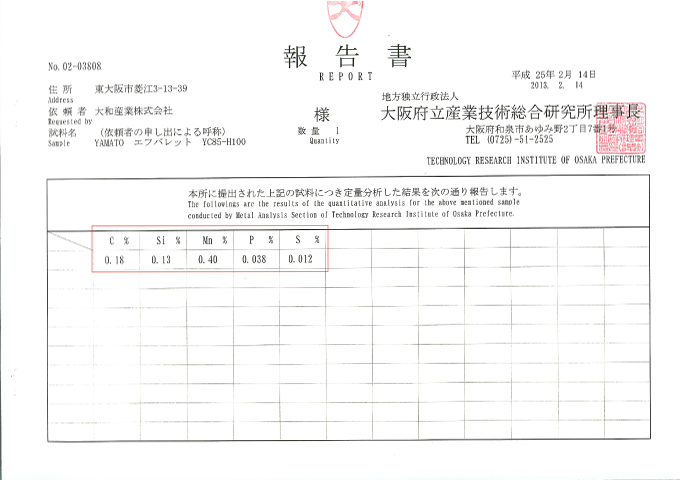

2.3 The Measure Method of Tensile Strength, Yield Point, Yield Strength, Elongation and Cold Bending

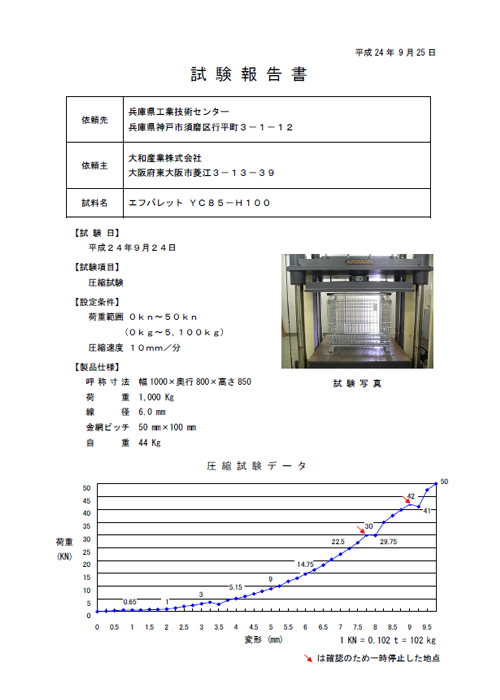

【Test Method】

Mechanical properties of the tensile strength, yield point, yield strength, elongation, cold bending.

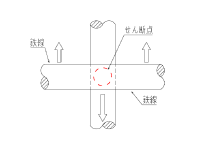

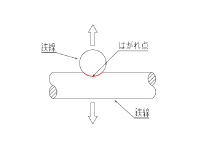

Figure 1 shows the schematic diagram of tensile test method. Photo 1 is a universal testing machine. The maximum stress to be read on universal testing machine is the tensile strength of the wire rod when it is be pulled to broken. Figure 3 is a tensile stress-strain curve when a wire rod is pulled. As shown in figure 3, the stress-strain curve of Q195 and Q235 wire rod is totally different , it is clearly identified that the yield point, tensile strength of them is much different.

In figure 3, the position of "X" is the actual breaking point when the wire rod is stretched and its cross-sectional area keeps reducing until broken. Point E is where even removed the load , the deformation of the test wire rod can't restore to its original form. The deformation before Point E is called elastic deformation, point E is the yield point, the stress of point E is called the yield stress or yield strength. After Point E is plastic deformation. Before the yield point, the deformation and the tensile force is a linear relationship, after the yield point, it becomes the quadratic linear relationship (parabolic), namely the small increase of tensile force leads to big deformation. To keep increasing load till to maximum value(this number calls tensile strength), afterwards, the output of tension of the universal testing machine changes small, however, the wire rod ruptures, reached to the breaking point (the position of "X" in figure 3). Usually , the tension of the plastic deformation of 0.2percent is as the yield strength of steel. Generally, to use steel material in safety, the stress range should be less than a quarter of the tensile strength , or 62.5percent of the yield strength. If beyond this range, the products made by this raw materials is not safe, it may be collapse, suddenly ruptured and other disastrous accidents which may cause casualties.

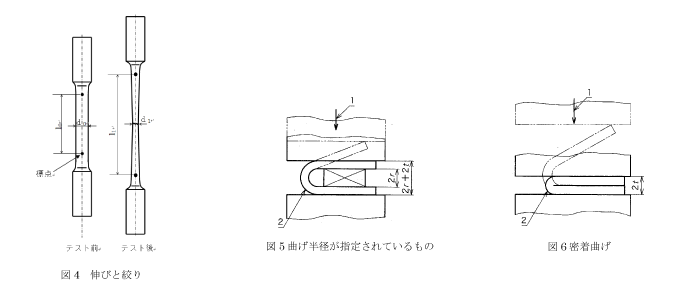

【The Measure of Elongation】

Elongation is also measured by the universal testing machine.

To measure the length of the sample as L0 before test, to measure the sample length as L1 after test, the distance between the two fixtures is Lc=100 mm, the elongation calculation formula is as follows: Elongation(percent) = (L1 – L0)/Lc X100

【The Measure of Cold Bending】

For example, the 2 r of Q195 = 0, the 2 r of Q235 = 0.5 t. The cold bending of Q195.is shown in figure 6, The φ8mm wire rod of Q235 is shown in figure 5. The qualified material criteria is "without breaking and cracking.

Note: 2 r = the bending diameter. t = the specimen thickness

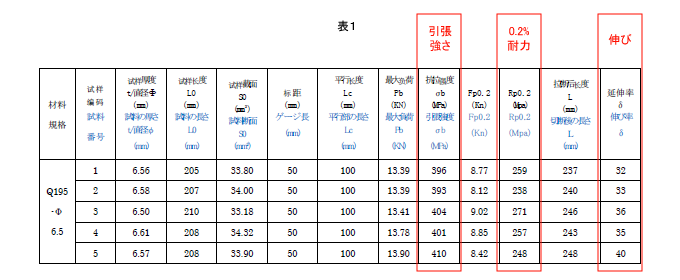

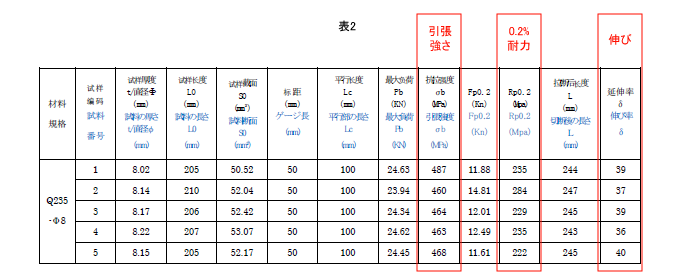

2.4 The Strength of the Wire Rod Q195-Φ6.5 mm and Q235 Φ 8.0 mm

As shown in table 1) and table 2), the tensile strength of Q195-Φ6.5mm is 400 MPa, the tensile strength of Q235-Φ8.0mm is 468 MPa. The tensile strength of Q235-Φ8.0mm is 17percent higher than Q195-Φ6.5mm.

Eastfound’s requirements of steel wire material which is used to make wire containers.

As our company's standards, the tensile strength of wire material ,which is used to make wire container, should be 420 ~ 500 MPa, the elongation should be greater than or equal to 30percent. All the wire materials we purchase need to be checked in random at 10percent , Only regarded as qualified if meet above conditions, otherwise, the materials need to be returned.

(Reference:the stretching of Q235 of Chinese national standard (GB) is more than 23percent, the stretching of SS400 Φ8.0mm of Japanese industrial standard (JIS) is more than 20percent)

|

|

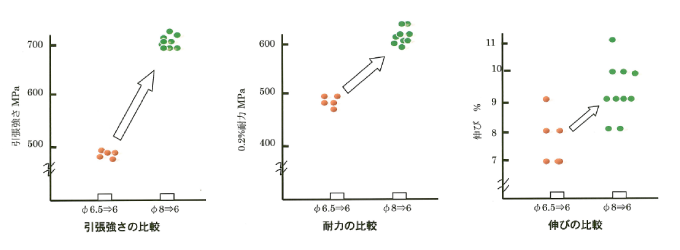

2.5 The Strength Comparison of Q195 Wire Rod Drawn from Φ6.5mm to Φ6.0mm and Q235 Wire Rod Drawn from Φ8.0mm to Φ6.0mm

In order to improve the strength and surface roundness of the raw materials, our wire material is drawn two times, firstly from Φ8.0 mm to Φ7.0 mm , secondly drawn fromΦ7.0 mm toΦ6.0 mm. The comparison data as below:

The strength comparison of Q195 wire rod drawn from Φ6.5mm to Φ6.0mm and Q235 wire rod drawn from Φ8.0mm to Φ6.0mm. The strength of Q235 wire rod is increased around 45percent after drawn from Φ8.0mm to Φ6.0mm. We think that the strength of wire container which is made of Q235-Φ6.0mm drawn from Φ8.0mm equals to the that made of Q195-Φ6.4mm.

The purpose of the 2 times of wire material cold drawn is completely removed the oxide skin of the raw material and guaranteed the roundness of wire rod and increased wire tensile strength.

Good roundness of wire rod, when resistance welding, can guarantee the stability of the welding penetration rate, fracture load and the torsion of welding points.

2.5.1 The strength comparison of drawn Q195 Φ6.0mm wire and Q235 Φ6.0mm

Using the wire rod , which is at most suitable parameter in tensile strength and yield strength and elongation, to make wire container, thus the strength of wire container should be at the best.

【reference 】1 MPa = 1 N/mm2.

Above is the comparison data of tensile strength, yield strength and elongation. Obviously, wire material drawn from Q235-Φ8.0mm to Φ6.0mm at 2 times is the best. Usually, in the processing of wire drawn, the thinner the wire drawn to, the higher the tensile strength and yield strength will be. However, the opposite is the wire material is too hard to break. In order to ensure the elongation of the wire rod still have 10percent after drawn 2 times, the elongation of raw materials in our company should have 30percent or more, in this way, it can guarantee there is no problem during welding and bending processing.

3 The Resistance Welding Technology of Q235 Wire Rod

Using Q235-Φ6.0 mm , which is drawn from Φ8 mm , to produce wire container, it is not easy to weld due to the strength of the wire material is high and it is very hard. In order to solve many welding problems, our company adopted the automatic resistance welding machines.

The feature of automatic resistance welding machine is welding process programming which can set the most suitable material resistance welding parameters (current ・time ・ pressure etc.). Under suitable conditions, the welding penetration rate is controllable, to ensure the strength of the wire mesh panel. In addition, there is no miss welding and the penetration rate is uniform, therefore, the product has very few deformation and welding burrs.

|

|

|

|

|

|

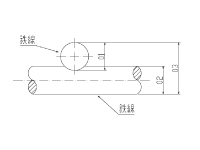

※Welding Penetration rate = (D1 + D2 - D3)/D1 x 100percent Note: if there is different wire diameter welded together, the small wire diameter is taken as D1 to calculate the penetration rate. |

|

※The test of shear strength The biggest strength when cut off the welding points. The direction of the force →the direction of the shear force is perpendicular to the direction of the welding stress. Unit: kN |

|

※The test of torsion The biggest torsion when the weld is disconnected The direction of the force →the direction of torque force is parallel to the direction of welding stress. Unit: N・m |

|

|

|

4 The Explanation of the Wire Container Base

Our company is using the Japanese CO2 welding robots.

The quality inspection of CO2 welding in our company is to test welding section with nitric acid which could judge the welding penetration rate is in good condition or not.

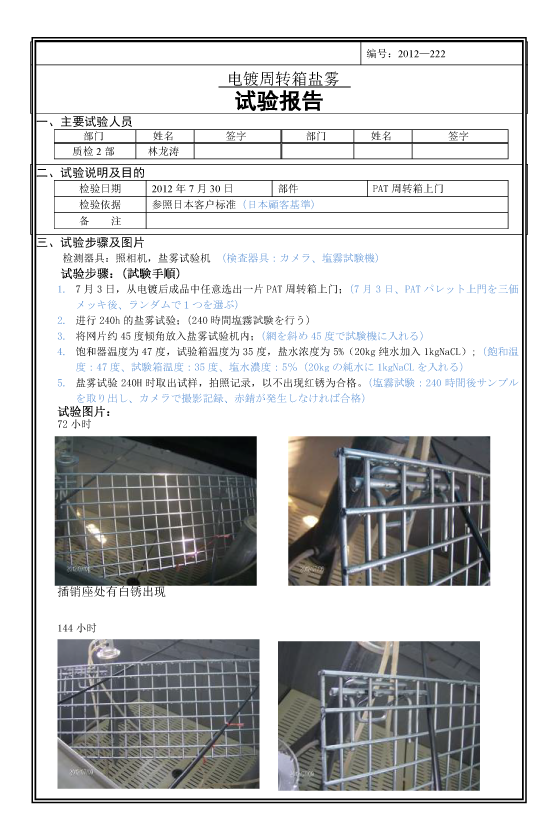

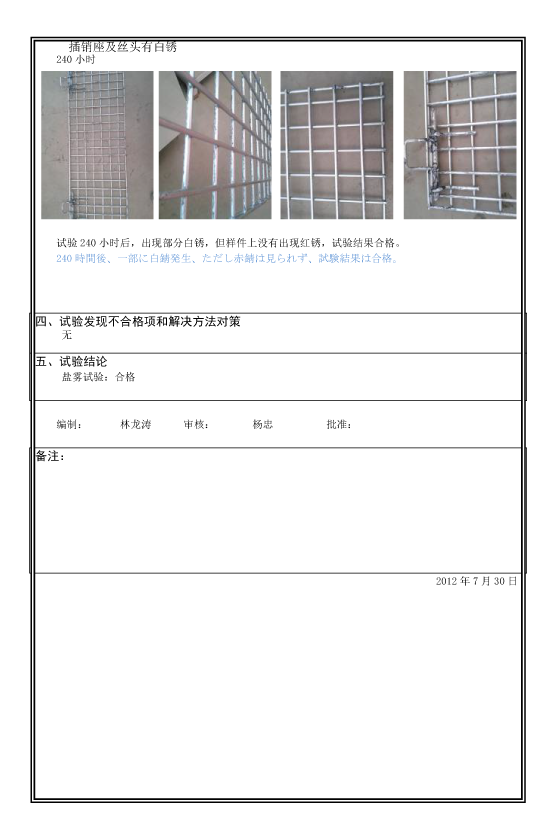

5 The Explanation of the Anti-Rust Test under JIS Standard.

The surface treatment in our company equals to JIS H 8610 "two level 3" surface treatment. Through 240 hours of salt spray test to check if appears red rust.

The spot check in random after 3 plus zinc plating

The test result and test conditions are as follows.

6 To Test the Strength of a Product

|

|