-

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

-

Wechat: a18350222213

Wechat: a18350222213

-

Time:1/7/2026

-

Time:12/30/2025

-

Time:12/18/2025

-

Time:12/10/2025

- CONTACT US

- Wechat: a18350222213

- aceally4@aceallygroup.com

Industry News

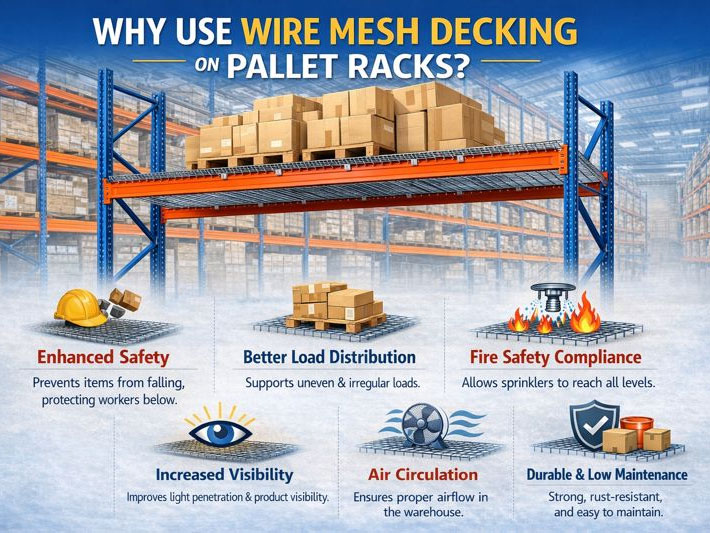

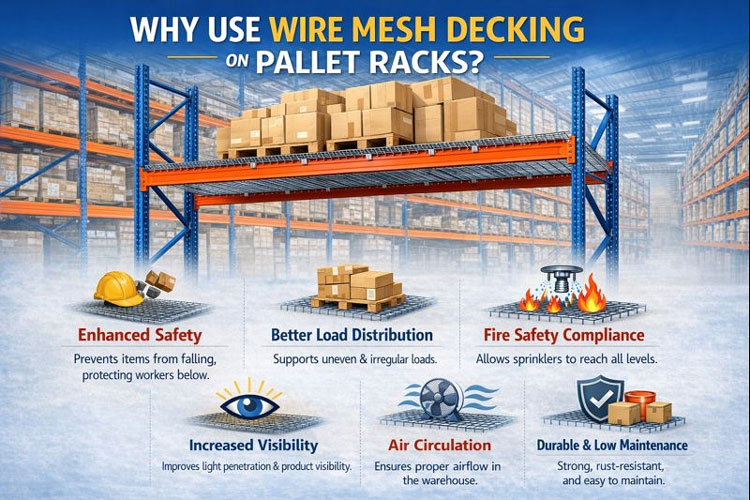

Why Use Wire Mesh Decking on Pallet Racks?

Time:1/7/2026

Time:1/7/2026 6

6Share:

In modern warehouses, pallet racking systems are designed not only for storage efficiency but also for safety, visibility, and fire protection. One critical component that is often overlooked is wire mesh decking. While beams support the pallets, it is the wire mesh decking that provides a stable and secure surface for goods of all shapes and sizes.

So why is wire mesh decking such an important part of a pallet racking system?

1. Enhanced Safety for Goods and Personnel

Wire mesh decking prevents pallets, cartons, and loose items from falling through the racking structure. This greatly reduces the risk of product damage and, more importantly, protects workers walking or operating equipment below the rack levels. Unlike solid panels, wire mesh allows debris to fall through instead of accumulating and creating unstable loads.

2. Better Load Distribution

Not all pallets are perfectly sized or in good condition. Some loads are irregular, overhanging, or stored in cartons rather than on full pallets. Wire mesh decking creates a continuous support surface across the beams, helping distribute weight evenly and preventing point loads that could damage beams or cause pallet collapse.

3. Improved Fire Safety Compliance

Wire mesh decking allows water from sprinkler systems to pass through easily in the event of a fire. This ensures that lower rack levels receive adequate sprinkler coverage, helping warehouses comply with fire codes and reducing the risk of fire spreading due to blocked water flow, which is a common issue with solid shelves or wood panels.

4. Increased Visibility and Light Penetration

The open structure of wire mesh improves visibility throughout the warehouse. Light can pass through the rack levels, making it easier for operators to identify products, inspect loads, and work safely. This contributes to a brighter, more organized working environment.

5. Improved Air Circulation

Good airflow is essential in warehouses storing food, pharmaceuticals, or temperature-sensitive products. Wire mesh decking allows air to circulate freely, helping maintain consistent temperature and reducing moisture buildup that could damage goods or packaging.

6. Durability and Low Maintenance

Wire mesh decking is typically made from galvanized or powder-coated steel, making it resistant to corrosion, deformation, and impact. Compared with wooden boards, it does not warp, rot, or attract pests, and it requires virtually no maintenance over its service life.

7. Flexibility for Different Storage Types

From standard pallets to cartons, drums, and small parts, wire mesh decking adapts to a wide variety of storage needs. It can be easily repositioned or replaced when rack configurations change, making it ideal for warehouses that frequently adjust layouts or inventory types.

Conclusion

Wire mesh decking is far more than just an accessory for pallet racking. It is a key safety component that enhances load stability, improves fire protection, increases visibility, and supports a wide range of storage applications. By investing in quality wire mesh decking, warehouses can achieve a safer, more efficient, and more compliant storage environment.