-

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

-

Wechat: a18350222213

Wechat: a18350222213

-

Time:10/29/2025

- CONTACT US

- Wechat: a18350222213

- aceally4@aceallygroup.com

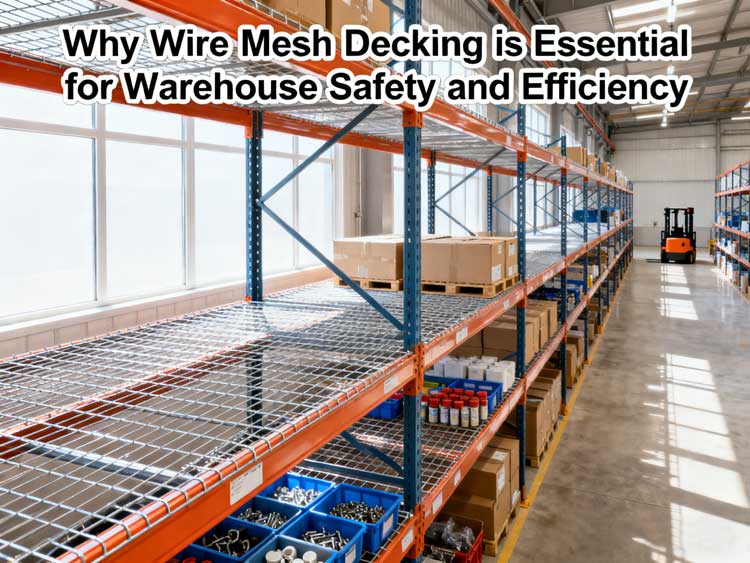

Why Wire Mesh Decking is Essential for Warehouse Safety and Efficiency

Time:11/17/2025

Time:11/17/2025 11

11In modern warehouse management, wire mesh decking plays a critical role in enhancing both safety and operational efficiency. It serves as a sturdy, reliable solution for organizing and storing goods in pallet racking systems.

This article will explore how wire mesh decking contributes to warehouse safety and efficiency, offering a durable and cost-effective alternative to traditional solid decking.

What is Wire Mesh Decking?

Wire mesh decking consists of interwoven metal panels designed to fit into the beams of pallet racking systems.

These open-grid structures allow for airflow and better visibility, providing a practical and flexible solution for storing various products.

Typically made from high-strength steel, wire mesh decking is used across a variety of industries, from manufacturing to retail and logistics.

How Wire Mesh Decking Enhances Warehouse Safety

1. Increased Load Distribution

Wire mesh decking helps evenly distribute the weight of stored goods across the racking system. This balanced load distribution reduces the risk of racking failure or instability, ensuring the safety of both the warehouse infrastructure and the workers.

- ✓ Ensures the racking system can support high loads without bending or collapsing.

- ✓ Prevents concentrated weight on any single section of the shelf, avoiding potential damage.

2. Reduces Risk of Items Falling

In high-traffic warehouses, the risk of items falling from shelves is significant. Wire mesh decking provides a secure and stable platform for products, reducing the chances of inventory falling and causing injuries.

- ✓ Provides a barrier that prevents items from slipping off shelves.

- ✓ Enhances stability and reduces risk of accidents from falling products.

3. Improves Visibility for Better Safety

The open-grid structure of wire mesh decking improves visibility within the warehouse. This transparency allows workers to quickly identify issues such as misplaced products or unsafe stacking practices, reducing the likelihood of accidents.

- ✓ Allows easy identification of potential hazards.

- ✓ Improves workflow by enhancing worker awareness of inventory placement.

How Wire Mesh Decking Improves Warehouse Efficiency

1. Better Inventory Management

Wire mesh decking significantly improves the efficiency of inventory management by offering better visibility and accessibility. The open design allows workers to quickly assess product levels and conditions without needing to move items around.

- ✓ Enables easy access to stored goods, reducing retrieval time.

- ✓ Helps organize inventory in a more systematic manner.

2. Optimizes Space Usage

Unlike solid decking, which can trap dust and debris, wire mesh decking allows for better airflow, contributing to a cleaner and more organized storage area. This efficient use of space also helps maintain a more hygienic environment, especially when storing sensitive or perishable items.

- ✓ Maximizes storage capacity by allowing for better air circulation.

- ✓ Helps keep storage areas cleaner by reducing dust buildup.

3. Facilitates Faster Picking and Packing

The improved visibility and easy access to products help speed up the picking and packing process. Warehouse workers can quickly identify products, reducing the time spent on order fulfillment.

- ✓ Reduces downtime by speeding up the picking process.

- ✓ Enables quicker order fulfillment, improving overall efficiency.

Durability and Cost-Effectiveness of Wire Mesh Decking

1. Long-Lasting Materials

Wire mesh decking is made from durable steel, which is highly resistant to wear and tear. Unlike other materials, wire mesh can handle heavy loads without warping or deteriorating, offering a long lifespan with minimal maintenance.

- ✓ Supports heavy-duty storage needs without failure.

- ✓ Requires less frequent replacement, making it a more cost-effective choice.

2. Flexible and Adaptable for Future Needs

Another advantage of wire mesh decking is its adaptability. Available in a range of sizes and configurations, it can be customized to fit different racking systems. As warehouse storage needs change, wire mesh decking can easily be adjusted to accommodate new product types or layouts.

- ✓ Easy to adjust or reconfigure as warehouse needs evolve.

- ✓ Can be customized to fit different racking setups, improving overall flexibility.

Conclusion

Wire mesh decking is a highly effective solution for enhancing warehouse safety and efficiency. Its open-grid design provides numerous benefits, including better load distribution, improved visibility, and reduced risk of product damage or worker injury. By offering a flexible, durable, and cost-effective solution for managing warehouse inventory, wire mesh decking helps warehouses maximize their storage potential and maintain a safer, more organized environment.

Integrating wire mesh decking into your racking systems is a smart choice for any warehouse looking to improve safety, efficiency, and long-term cost-effectiveness. Whether you’re dealing with heavy loads or sensitive products, wire mesh decking can be a key component in optimizing your storage operations.