-

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

-

Wechat: a18350222213

Wechat: a18350222213

-

Time:1/7/2026

-

Time:12/30/2025

-

Time:12/18/2025

-

Time:12/10/2025

- CONTACT US

- Wechat: a18350222213

- aceally4@aceallygroup.com

Component for enhancing warehouse efficiency: wire mesh deck

Time:10/15/2025

Time:10/15/2025 91

91In modern warehousing and logistics systems, details determine efficiency and safety. The Wire Mesh Deck, a key component of storage equipment like pallet racking and mezzanine platforms, may seem simple in structure, but it plays an indispensable role in the overall system. This article delves into the functional advantages, application scenarios, and key selection points of Wire Mesh Decks, helping you fully understand this core component for boosting warehouse efficiency.

1. What is a Wire Mesh Deck? Why is it So Important?

- Basic Definition and Core Functions

A Wire Mesh Deck, often called "storage mesh decking" or "rack mesh decking" in Chinese, is a load-bearing panel made of high-strength metal wires welded into a grid pattern. It is specifically designed to be placed on the beams of pallet racking, creating a sturdy load-bearing surface. Its core function is to support goods. Unlike using wooden or steel plates directly, the grid structure of the Wire Mesh Deck offers unique advantages, effectively solving various common pain points in warehouse operations.

- Solving the Pain Points of Traditional Storage

In traditional warehouses not using Wire Mesh Decks, hazards exist when using wooden planks directly or placing goods directly on the beams. Wooden planks are prone to damage, are not fire-resistant, and can pose uneven load-bearing risks. Using beams directly to support smaller items can easily lead to falling goods. The emergence of the Wire Mesh Deck provides a safe, durable, and versatile solution, fundamentally enhancing the reliability of the storage system. It is an essential element for achieving modernized and refined warehouse management.

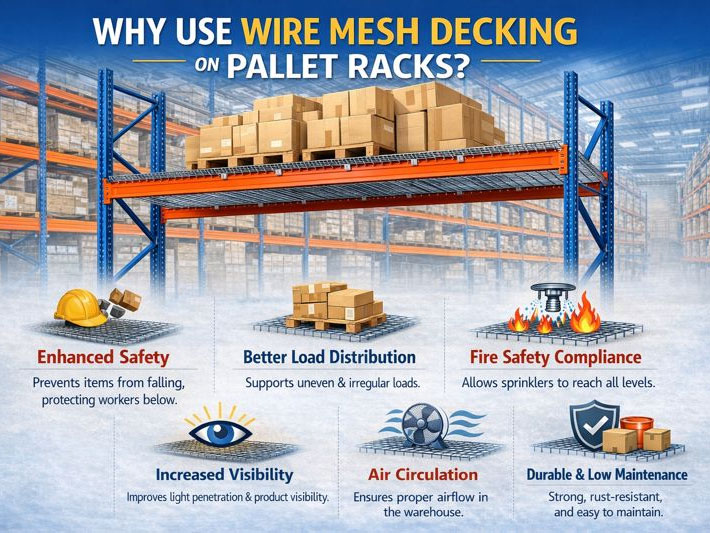

2. Four Irreplaceable Advantages of Wire Mesh Decks

- Excellent Fire Resistance and Ventilation

The open grid structure of the Wire Mesh Deck is one of its greatest features. This design provides excellent ventilation, which is crucial for storing goods like food and chemical products that require air circulation, effectively preventing heat buildup and mold. Simultaneously, its all-metal material gives it a Class A fire resistance rating, completely eliminating the fire hazard associated with wooden planks and significantly improving the overall fire safety level of the warehouse.

- Unparalleled Dust Prevention and Drainage Capability

In environments with high cleanliness requirements, such as food and pharmaceutical warehouses, the accumulation of dust and debris is unacceptable. The grid structure of the Wire Mesh Deck allows dust, debris, and small particles to fall directly through the mesh holes, preventing accumulation and facilitating cleaning, perfectly meeting food-grade storage hygiene standards. Similarly, in humid environments or situations requiring washing, it drains quickly, does not retain water, and prevents goods from being soaked and metal components from rusting.

- Superior Load Capacity and Long-Term Durability

Manufactured from high-quality steel and welded, Wire Mesh Decks possess high structural strength and load-bearing capacity. Their load-bearing range is wide and can be customized according to needs, commonly reaching over 500kg/㎡. Furthermore, the surface is usually treated with galvanizing or powder coating, providing excellent corrosion resistance and wear resistance. Their service life far exceeds that of wooden decking, making them the ideal choice for achieving high load-bearing capacity in heavy-duty rack grid panels.

- Comprehensive Safety Assurance

3. How to Choose the Right Wire Mesh Deck for Your Warehouse?

- Define Application Scenarios and Requirements

The first step in choosing a Wire Mesh Deck is to clarify your usage scenario. Is it for standard pallet racking or a mezzanine platform? What type of goods are being stored? Are they boxed items, bagged items, or small parts? Is frequent washing required, or is the environment highly humid? Answering these questions will help you determine the required mesh size, wire diameter specification, surface treatment, and whether reinforcement bars are needed.

- Key Parameters: Wire Diameter, Mesh Size, and Dimensions

Wire Diameter: Determines the overall strength of the deck. Thicker wire generally means higher load capacity.

Mesh Size: Chosen based on goods size and ventilation/dust-fall needs. Small mesh is suitable for preventing small items from falling, while large mesh offers better ventilation and drainage.

Dimensions: Must precisely match your rack beam spacing, ensuring sufficient support around the edges and safe placement on the beams. The dimensions for warehouse mezzanine platform mesh decking usually need to closely match the platform structure.

- Focus on Workmanship and Surface Treatment

A high-quality Wire Mesh Deck should have firm, uniform weld points and be flat overall without deformation. The surface treatment method directly affects its service life. Hot-dip galvanizing offers a thick layer and strong corrosion resistance, suitable for humid environments; electro-galvanizing has a more aesthetic appearance and lower cost; powder coating can provide a variety of color options, is aesthetically pleasing, and offers certain corrosion and scratch resistance.

4. FAQ about Wire Mesh Deck

Q1: What is the load capacity of a Wire Mesh Deck?

A1: Load capacity varies depending on wire diameter, mesh design, and the presence of reinforcement bars. Standard products can typically achieve dynamic loads (during forklift operation) of 500-1000kg/㎡, with static loads being even higher. When selecting, be sure to provide your specific load requirements to the supplier to get the accurate specification.

Q2: Can it be used on existing racks?

A2: Absolutely. Wire Mesh Decks are very flexible upgrade components. As long as your rack's beam spacing is clear and the structure is sound, you can order decks of the corresponding size for direct installation, without any modification to the rack itself. It is the premier choice for an economical rack upgrade solution.

Q3: What are the pros and cons of Wire Mesh Decks compared to Steel Sheets/Plates?

A3: Wire Mesh Decks are superior to solid steel sheets in terms of ventilation, fire resistance, dust prevention, drainage, and self-weight, and are usually lower in cost. Solid steel sheets might have an advantage when bearing extremely concentrated heavy loads (e.g., on very small contact points) and can completely prevent small items from falling. The choice depends on your specific storage needs.