-

E-mail:

aceally4@aceallygroup.com

E-mail:

aceally4@aceallygroup.com

-

Wechat: a18350222213

Wechat: a18350222213

-

Time:6/25/2025

-

Time:6/24/2025

-

Time:6/18/2025

- CONTACT US

- Wechat: a18350222213

- aceally4@aceallygroup.com

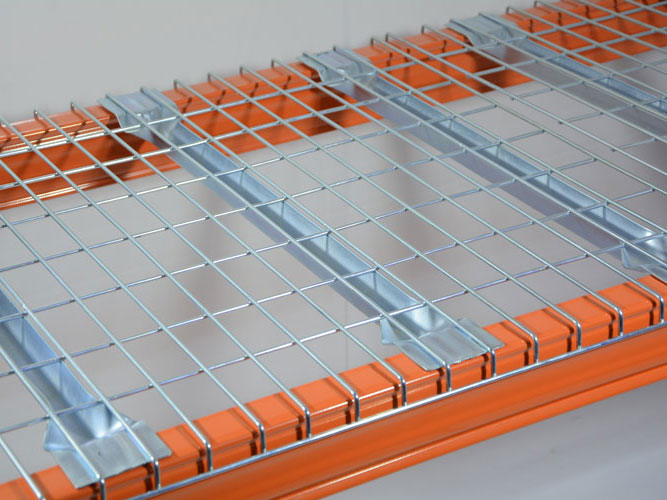

How to maintain the wire mesh decking to extend the service life?

Time:3/28/2025

Time:3/28/2025 342

342I. Surface Treatment (Existing Shelf Remodeling)

1. Spraying anti-rust paint

After cleaning the wire mesh decking surface, spray epoxy anti-rust primer + polyurethane top coat to form a physical isolation layer.

Operation suggestion: Thoroughly remove rust before spraying (with sandpaper or sandblasting) to ensure even coverage of paint.

2. Powder Electrostatic Spraying

The powder coating (e.g., epoxy resin) is cured on the metal surface by an electrostatic adsorption process, which is wear-resistant and corrosion-resistant, and suitable for batch processing.

Advantages: even coating without dead angle, environmental protection without solvent volatilization.

3. Immersion molding treatment

The wire mesh decks are immersed in molten plastic (e.g., polyethylene) to form a thick protective layer, and the anti-rust effect is better than that of ordinary spraying.

Applicable scenes: commonly used in outdoor shelves or high-humidity environments.

II. Environmental control (root cause prevention)

1. Control humidity

Rack warehouse humidity is recommended to be controlled below 60% for a long time, which can be realized by the following ways:

Installing an industrial dehumidifier or air conditioner;

Increase ventilation equipment (such as exhaust fans);

Avoid placing racks close to the walls to maintain air circulation.

2. Isolation of corrosive sources

If the warehouse stores chemicals (e.g. acids, salts, alkalis), they need to be stored in separate zones and sealed more tightly;

Regularly clean the surface of the warehouse racks to avoid the accumulation of corrosive dust.

III. Daily maintenance (low-cost program)

1. Regular inspection and cleaning

Wipe the racks with a dry cloth every month, and clean up water stains and dirt in time;

In case of localized rust, immediately polish with sandpaper and supplement with anti-rust paint.

2. Use anti-rust oil/wax

Apply a thin layer of anti-rust oil (e.g, WD-40) or anti-rust wax on wire mesh decking seams and welds to form an oil film to isolate water vapor.

3. Avoid mechanical damage

Prevent hitting the warehouse racks when handling goods, as scratching the coating will accelerate rusting.